There are five specifications of scraper conveyors in this series, and the models are:

XGZ-6 XGZ-8 XGZ-10 XGZ-12 XGZ-14

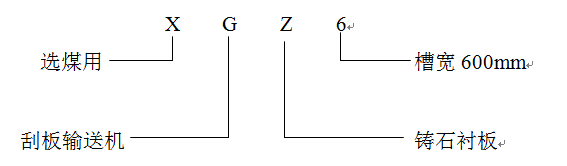

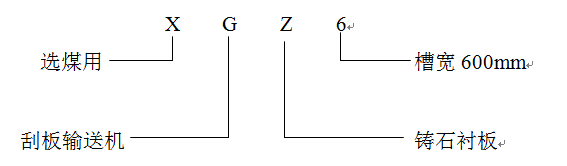

The model meaning of XGZ type cast stone scraper conveyor is:

The width of the conveyor trough starts from B=600mm and varies by 200mm to B=1400mm.

To meet the requirements of time use, two sizes are specified for the center height of the head wheel with three groove widths of B600, B800, and B1000, namely H=640mm and H=440mm; The center height of the B1200 and B1400 groove width head wheels is only available in one size, H=640mm.

Application and scope of XGZ type cast stone scraper conveyor:

Scraper conveyor is mainly used for the transportation and distribution of various types of coal with different moisture content and particle size below 300mm inside and outside the coal preparation plant and in the ground production system of coal mines.

It can be transported horizontally or diagonally, and horizontal transportation can be divided into single-layer transportation and double-layer transportation. During inclined transportation, only single-layer transportation is allowed. This series is designed primarily for horizontal transportation.

Overview of the Structure of XGZ Cast Stone Scraper Conveyor

The XGZ scraper conveyor is mainly composed of a driving part, a machine head, a middle groove, a tail, a scraper chain, etc. The transmission route is as follows: the torque of the electric motor is transmitted to the active sprocket shaft group through the coupling and reducer, thereby pulling the scraper chain to move and form a closed traction system.

1. Drive Department

The driving part is the power part of the conveyor, consisting of a motor, high-speed coupling, planetary gear reducer, low-speed coupling, etc., all components are uniformly installed on the driving base. The drive unit is divided into linear and vertical types according to its layout. The vertical type is mainly used in situations where the installation position is relatively narrow.

2. Head section

The head of the machine is composed of a head frame, a head wheel set, etc. The head wheel set is the transmission component for the operation of the scraper chain, mainly composed of the main shaft, bearings, bearing seats, sprockets, etc. The sprocket of this machine is a detachable structure. After the sprocket has been worn out for a period of time, the connecting bolt of the sprocket can be removed, and the sprocket can be divided into two halves and removed by gently tapping with a hammer, reducing maintenance time. The tail of the machine head is connected to the middle groove flange.

3. Middle groove

The intermediate groove is the main part of the conveyor for material transfer, which is composed of several 3-meter standard intermediate grooves and one to two connecting grooves according to the needs of the machine. Each part is connected with end flanges and bolts. According to user needs, it can be divided into single-layer and double-layer intermediate slots, and can be equipped with electric and manual gates to achieve bidirectional conveying and unloading at any point. The middle groove is placed on the lower support leg, and the support leg can be fixed in the appropriate position of the groove body according to the user's needs (be careful not to touch the reinforcing ribs at the bottom of the groove). After on-site installation, cast stone is laid on the bottom of the groove and the guide rail of the scraper chain. The upper part is a sealed structure, and during maintenance, the upper bolts can be removed to open the upper cover.

4. Tail of the aircraft

The tail of the machine consists of a tail frame, a tail wheel assembly, and a tensioning device. The front part is connected to the middle groove with a flange. The screw of the tail tensioning device is adjusted to tighten the bearing seat of the tail wheel assembly, and the tension degree of the chain can be adjusted.

5. Scraper chain

Scraper chain is the main body for transporting coal and also one of the key components of the conveyor. Mainly composed of chain links, connecting rings, and scrapers.

When installing the XGZ type cast stone scraper conveyor equipment, relevant regulations should be followed, and some specific details are as follows:

1. Transporters with gates require that the drive device frame, nose, tail frame, intermediate groove support, etc. be padded with a cement platform of 30mm or more. Transporters without gates should also be padded with a cement platform of 30mm or more. If there are special requirements, it is allowed not to be padded. When installing the middle groove, install it in sequence according to the outer side of the middle groove.

2. Require installation to be straight, and after all bolts are tightened, lay the cast stone slabs uniformly according to the drawing requirements. The adhesive shall be selected by the construction unit and strictly constructed according to the operating procedures. After drying, it shall be operated in a blank line.

3. When assembling the chain, place the vertical welding joint of the chain upwards (i.e. the vertical welding joint faces away from the sprocket), and the flat welding joint faces the centerline of the chain. Connect the concave surface of the ring upwards and the plane downwards (i.e. the plane faces the sprocket).

4. After the installation of the whole machine, it should be air operated for 4 hours. After operation, the temperature rise of the bearings should not exceed 30 ℃, the bolts of each part should not be loose, the cast stone plate should have no obvious collision marks, and the reducer should meet the requirements. The transportation of the gate should be unobstructed, and the gaps between each part should comply with regulations. During operation, it should be smooth, without any impact, vibration, or other phenomena. The tension of the chain is uniform, the temperature rise of the bearings does not exceed 30 ℃, and finally a uniform spray of paint is applied.

5. During the installation of the entire machine, appropriate rubber pads or other materials can be used to adjust the gap between the middle groove flanges and ensure the straightness of the total length.